Climbing Arborist Blog

New WorkSafe BC Arborist Regulations for British Columbia

By Ryan Senechal |

WorkSafe BC has approved proposed amendments to Part 26: Forestry Operations to include a subsection for Arborist Activities. There is a four month transition from the Board of Director’s approval of this amendment to when it becomes law on December 1st, 2021. You can review the changes here: https://www.worksafebc.com/en/law-policy/public-hearings-consultations/closed-public-hearings-and-consultations/bod-approves-2020-and-2021-amendments-ohsr-may-2021

Will this have implications for your workplace and more directly your own work practices? Yes. Why are these regulations being adopted? Industry has not effectively addressed the rate of fatal and severe injury incidents to workers in the province, and the high insurance premiums or non-compliance penalties Tree Services pay haven’t deterred dominant behaviours. Through consultations with industry leaders representing different segments of the industry, WorkSafe BC has implemented regulations that will be an adjustment for small and large businesses alike.

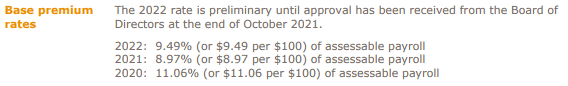

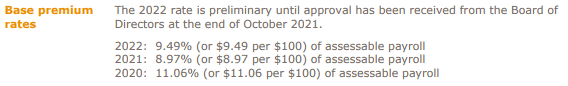

Source: WorkSafe BC Tree Services Classification Unit Description and Rates

Reactions to these regulatory changes were mixed during the consultation period; resistance from some vocal industry participants targeted time and money. Yes, initially these changes will cost time and money. The playing field is about to be legally levelled with a recipe that promises to address our industry’s high rate of incidents. We can anticipate some will opt out of compliance although WorkSafe BC has assured us that Prevention Officers will be provided training ahead of adoption (December 1st, 2021) and that Tree Services will be a focal point for site inspections.

Key themes of the new Arborist Activities amendment to Part 26 of WorkSafe BC’s Occupational Health and Safety Regulation include definitions, arborist activities planning, tree climbing equipment, tree climbing planning, and tree climbing procedures. The entire part has been framed as a non-prescriptive, best practices approach which will require some legwork for workplaces to demonstrate compliance and due diligence. For the many Arborists working in BC having been trained outside of the province or out of the country, this new regulation could improve working conditions as credentials, training, education and experience from outside of the province becomes recognized. For example, OHSR Part 26.1: Definitions describes the following:

“qualified arborist”

means a person who

(c) has, as appropriate to the work being done, knowledge, through training or a combination of education and training, of and experience

Note that there is no measurement of experience, knowledge or training, or examples given of what education might be “appropriate to the work being done”. To paraphrase, Qualified Arborist means a person who has demonstrated beyond a reasonable doubt to a panel of occupational health and safety peers (including industry subject matter experts) that the person is competent to perform the task they have been assigned to complete. This is not simply tree climbing, but most scenarios a tree climber is likely to encounter. Third party industry trainers and credentialing organizations have an important role in supporting workers to demonstrate compliance with this definition of Qualified, although internal workplace training may suffice so long as the trainer is Qualified and the training provided meets industry standards/best practices.

Flexibility enabled through this non-prescriptive approach can lead to confusion and frustration, and this is where collaboration with your regional tree care community partners can be quite helpful. One source of confusion and handwringing through the consultation phase of this amendment was related to Part 26.12.0.3 which provides context for inspections of trees and creation of a tree climbing plan, and the requirement for the documenting of that plan. Imaginations ran wild on this section, with suggestions that this added time tax burden would drive owners out of business. While there will undoubtedly be some time cost associated with completion of a site level hazard assessment, our industry’s safety performance continues to lag behind other industries that have taken strides to measurably reduce rates of incidents. A document alone offers no physical protection from harm, but the process of crew participation in a site level hazard assessment has time and again proven its value in reducing incidents, in preparing workers to respond quickly and effectively in emergencies, and to support an improved workplace safety culture.

Tree workers transitioning into compliance with this new regulation can take a few important steps to help make this process relatively painless so we can get to the benefits sooner (fewer workers being hurt or killed on the job):

Let your employer know about these regulatory changes and offer your support in reaching compliance. Although efforts have been made to spread the word about this new regulation, many workplaces will have no idea of its existence. Employers do have a legal obligation to comply with the regulation although early adoption will only be possible if the employer is made aware of the new regulation and the workplace works together to implement required changes.

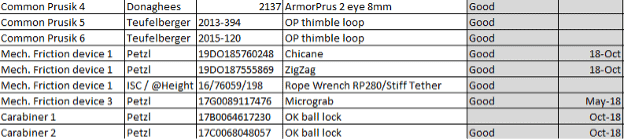

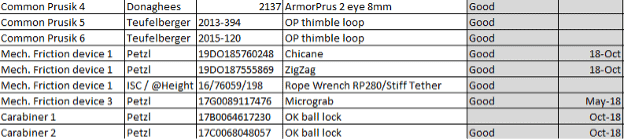

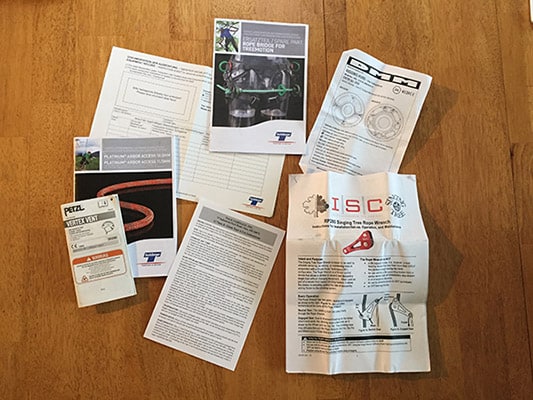

Create a PPE inspection spreadsheet. Documenting your fall protection and rigging equipment is one simple task that can address multiple requirements under Part 26.12.06 Tree-climbing equipment. The ISA ITCC has produced a PDF inspection formwith a simple layout that could be recreated unique to your workplace. From here on out, future gear purchases should be fit for the purpose of industrial tree climbing and certified/labeled with traceable product information. There must be technical information for the product that addresses inspection and retirement criteria, configuration, operating limits and load ratings, and these should be available to the gear owner in hard copy or digital format.

Make time with your crew to talk about the hazards, and document them before you start working. These are hazards specific to your work location and the tree(s) directly or indirectly involved in your work. For every hazard, identify controls you will put in place that will allow the entire crew to work safely around those hazards. Discuss the loads anticipated of required tree work on climbing and rigging anchors and plan systems to minimize the potential for overloading the structure or equipment. Finally, plan for emergencies unique to the conditions you are working in to enable a quick and effective response. All of this can be quickly captured on a tailgate, tailboard, site level hazard assessment, jobsite safety assessment, etc. You can ask nicely for a copy of a tailgate from one of your industry partners and modify it for your own workplace.

Strive for credentials or qualifications. Within the province of BC there is lots to choose from to validate your knowledge, skills, training and experience through qualifications and credentials. Qualifications that set a high benchmark through prerequisites and written/performance skills exams are valuable, as are credentials that set continuing education renewal requirements. Here are some examples:

ITA BC Arborist Technician Certificate of QualificationITA BC Climbing Arborist Certificate of Qualification

ISA Certified Treeworker Climber Specialist

ISA Certified Arborist

ISA Tree Risk Assessment Qualification

TCIA Certified Treecare Safety Professional

Keep your resume up to date. Any previous training you’ve received from beyond your workplace should be noted down to demonstrate your commitment to professional development. This can include webinars, conferences, workshops, courses and climbing competitions. Previous work experience is also valuable here, along with your roles and estimated hours performing common tasks. Restricted trades require a Qualified supervisor to sign off on an apprentice’s hours for specific tasks if the apprentice wishes to one day reach qualification. Our trade is not restricted at this time, but we can definitely do a better job of tracking our hours on rope, rigging, on a saw, or in a bucket truck as a starting point.

Check to see if your work practices meet the standard. Safe work procedures should be documented and immediately available to workers in the field. These can be developed in house, and should reflect objective criteria (such as ANSI Z133 for Arboricultural Operations) wherever possible. If your methods of approaching common tasks are not recognized by your industry partners or have been determined to be unacceptable for safety reasons, be prepared to defend your rationale if you want to continue using this method.

Thinking of this regulation as more of a carrot and less of a stick is to everyone’s benefit. As workplaces transition to reach this new standard set, fewer lost time injury incidents, fewer fatal incidents, and reduced insurance premiums will result. A little further down the road we might find reduced stigma associated with dangers of the tree care profession, longer careers and better quality of life for Arborists, and improved outcomes in recruiting new workers.

Have specific questions about the new Arborist Activities regulations? Let’s hear them.

Skills improve my efficiency; efficiency improve my skills!

By Dan Holliday |

Efficiency doesn’t seem like a sexy or glamorous subject when compared to discussing the latest and greatest climbing products or machinery on the market. But, for me at least, the new, shiny, expensive gear or the latest machinery I keep looking at in the Arbor magazines all play a part in improving my efficiency practices. Think about it - would you still buy a new ascender that was the coolest color, the nicest shape and had the best name, if you heard that it dragged badly on the rope causing a lot of friction and making your ascent more difficult?

With this prior knowledge, probably not.

Efficiency is accomplishing a task in the minimum amount of time with the least amount of energy expended.

In recent years, efficiency has become my favorite topic. It is something I focus on everyday across every aspect of my job. The more I focus on efficiency, the more I understand where techniques and systems can be improved upon. I realized that the way I work (for example, my climbing techniques) can improve much more quickly if I understand what I am doing, why I do certain things, and if I take time to analyze. This allows me to make major or minor tweaks with the aim to improve efficiencies.

Implementing efficient practices

To successfully implement efficient practices involves a mixture of planning, common sense and experience. If I am to complete a task I have never done before, I use the follow method: 1) I make a plan that I believe makes the most sense, in this particular situation; 2) I select the best equipment for the task; 3) I delegate relevant tasks to my crew who are most capable in these various roles; and

- complete the smaller tasks in a sequence that makes the most sense for accomplishing the job.

Once the job is complete, I can then analyze and take note of what worked well, what went wrong, and what worked but what can be improved upon for future jobs of this nature. It is this process of analyzing and being aware of my systems that allow me to become more efficient as each time I take on a similar task my efficiencies should improve.

The process of understanding and analyzing systems (climbing techniques, job planning, rigging setups, etc.) are key. If I didn’t pay attention to how things worked, I’d continue to use the same methods which would result in my evolution as an arborist becoming stagnant and I would miss opportunities to implement new, more suitable systems.

Looking at the bigger picture of an arborist’s career, implementing efficiency goals will result in less short- and long-term fatigue, career longevity, reduced chance of long-term muscle injuries, stress reduction and a constant learning curve as you evolve your skills.

Improving efficiency through experience

Recently, I and my team member, Conor, were tasked to remove a very tall, dead Hemlock tree. The location of the tree and gradient around the tree meant it would not be a straight forward and easy removal. There were multiple large trees nearby, so the best and most effective plan I could come up with was to set a rope between two live trees and install the rigging block in the middle of the rope that spanned the gap between these trees. We would then rig the Hemlock off this point which would make quite a large swing, hopefully, resulting in the pieces being rigged down into the flat driveway of the property. We used a rigging hub on the end of the rigging line as we needed to attach multiple ropes (a haul line for me as the climber, a tag line for Conor, the rigging line, and the webbing sling). A couple of pieces got hung up in some smaller trees close to the ground, but the job went well on the whole.

Conor, has only been in the industry for 3-4 years and he had never used or seen this exact setup and was unsure of how everything would work. Being a quick learner and problem solver, Conor gained a full understanding of the system and figured out the adjustments required to prevent issues by the time the job was complete. Conor will now take the experience from this job and be fully aware of all aspects of the rigging technique and where potential problems may lie when we next use this system. Thus, he is now a better crew member as a result of this thoughtful approach.

Key considerations

When considering efficiencies for an entire job or a singular technique, these are the key elements that I think about:

- Make a plan and be willing to make adjustments to improve efficiency.

- Try not to allow pressure to cause me to rush (rushing/panicking can result in poor decision making, not working with a systematic approach and not using the right equipment, or worse cause an injury).

- Choose the best tool or tools for the job.

- Select the best technique for the task, allocate jobs to crew members for completion in an order that makes sense.

- Share ideas and experiences with team members: discuss my favorite and least favorite techniques, talk about jobs that went well and those that did not go as well, and list the reasons why for each experience.

Saving time and energy with rigging systems

In the right situation, rigging systems can be a huge time and energy saver. Creating the most complex system for a specific scenario that may require a 2-hour setup are still more efficient than without this system. Moving wood without much effort to an end location, rather than using all manpower, can be absolutely amazing. For me, I always weigh the following options in my thinking process: How long will it take to set up the rigging components? How long do I estimate the job to take once rigging is set? How long

would the job take without this rigging or setup? If I feel like the rigging option will take the same amount of time or be quicker, I will always choose rigging. The reason for this is because if I can move wood in a way that reduces manpower and fatigue then I would prefer to save the crew’s the energy if I can complete the job in the same amount of time.

My obsession with efficiency!

The biggest gains I have made in the last 3-4 years relating to my tree climbing skills have come from my obsession with efficiency. Instead of thinking about my next move or task, I think about multiple tasks ahead of me. For example, my work positioning while using a chainsaw - I now focus on choosing the best lanyard configuration for the work, select the optimum lanyard location to make the maximum amount of cuts while not having to change lanyard position multiple times, and maintain a safe, comfortable position for cutting. Compare this to only looking at the next branch to remove or prune, putting on my lanyard, and then removing it after that one task. Doing that action for 8 limbs will eat into my time when I could select one lanyard position that allows me to reach all 8 limbs.

Another climbing-based technique I utilize to improve efficiency is to make undercuts on multiple branches with a chainsaw, then doing the top cuts using a handsaw when I need control. This maximizes the use of the chainsaw first to save energy.

Don’t let stubbornness stifle efficiency!

I have owned a battery powered, top handled chainsaw for a couple of years and love all the benefits that come from using it which I believe improve efficiencies in various capacities. There have been times, however, when I have continued to use the saw during removals for too long. As the wood gets too large, the saw begins to struggle. I then use more force which causes wear and tear on a tool that is not designed for purpose,all because I am enjoying my new favorite tool and didn’t allow myself to recognize when it was time to switch it out for something more suitable and efficient.

Good communication to create seamless operations

Another great form of efficiency is through clear communication. In recent years, Bluetooth communication headsets have become available for use in arborist helmets and have made a huge impact on my daily worksites. Communication has become so much easier while working. The crew can have a full conversation at a normal volume and tone, instead of the well-known screaming from high in a tree with single word demands. Even if those short instructions are said with the kindest of intent, they come across aggressive, hurried and always missing reasoning around the request. Instead, asking for equipment through a headset, (e.g. specific rigging equipment), you can ask for the exact components you require, where they are located, how you would like them configured and what your plan is.

If you are working with a crew of 3 or 4 people all wearing headsets, even when your conversation might only be with one member of the crew, the other people in your team will hear the entire dialogue. This means the whole team is in sync with how the jobsite is running, which roles to take on, and what to expect. If you have never used these headsets on a jobsite, hopefully, this short example is a brief insight into how useful and efficient headsets are, but you will really never know the full benefit until you actually use them.

Efficiency is so important within the tree service industry, the more we are all aware of each and every aspect of our day to day tasks and how they can improve, the better, more fun, more enjoyable, safer, and longer our careers will become.

2019 – A year in review for climbing arborists

By Dan Holliday |

2019 has been a very interesting year in arboriculture, there has been new equipment launched into the market, people are constantly experimenting with new climbing techniques to improve efficiency and there has been a huge shift in regulations within the U.K. Arb industry.

New equipment released in 2019

The Petzl Chicane was released early in 2019. Petzl has designed the Chicane to be used in conjunction with the Zigzag for stationary rope system climbing. The Chicane adds friction above the Zigzag to allow for smooth operation, the idea coming from the way the rope wrench adds friction above a hitch. The Chicane/zigzag combo has had rave reviews, although Petzl are still getting heat from diehard rope wrench fans.

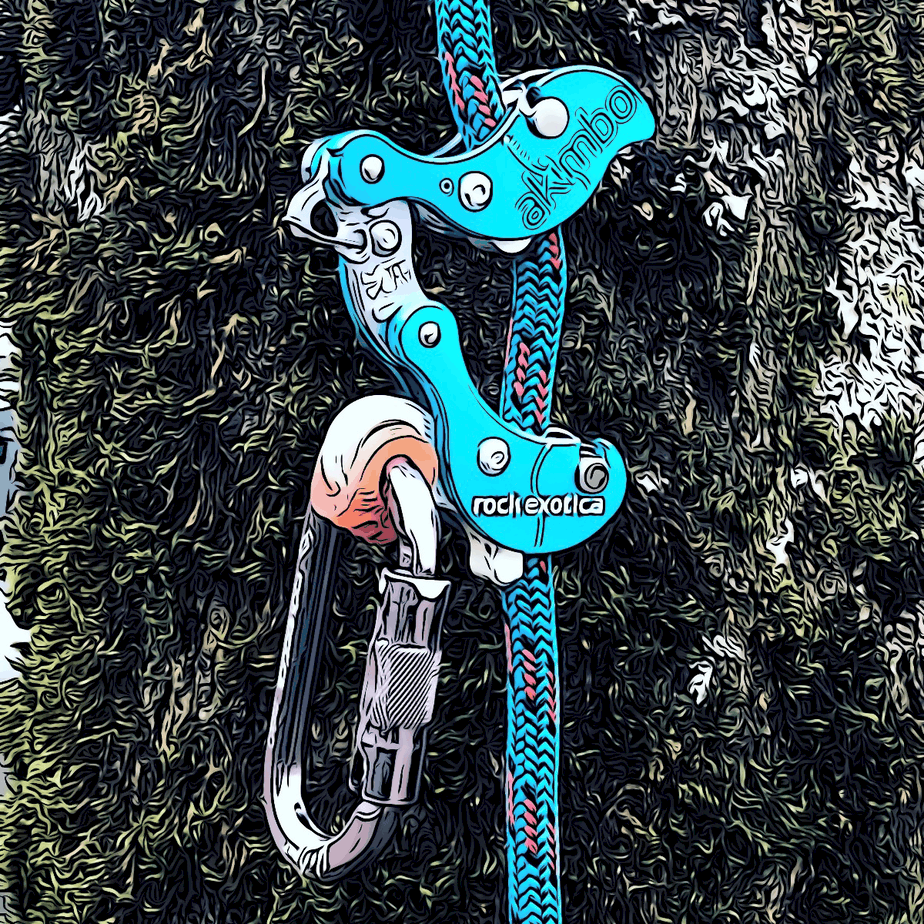

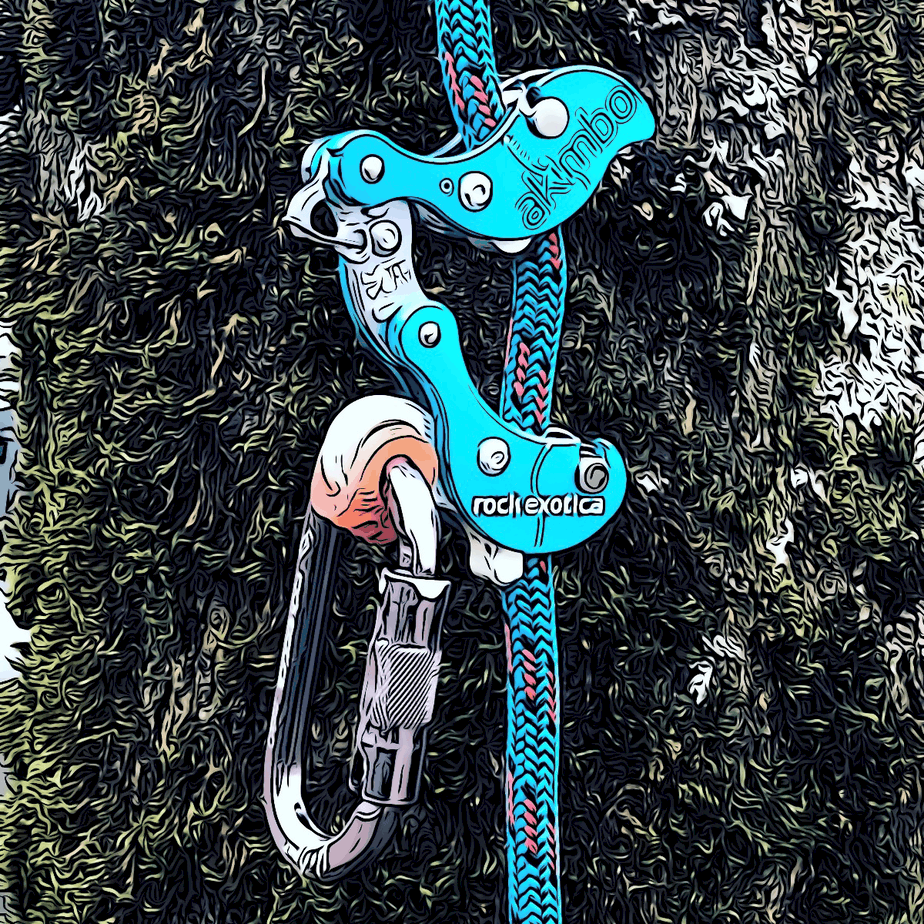

Rock Exotica finally released the much anticipated Akimbo. The Akimbo is a mechanical device that can be used both in stationary and moving rope systems (although primarily for SRS). The buzz for the release of the Akimbo was huge, and it seems to be flying off the shelves like hotcakes, although it has received mixed reviews across the board.

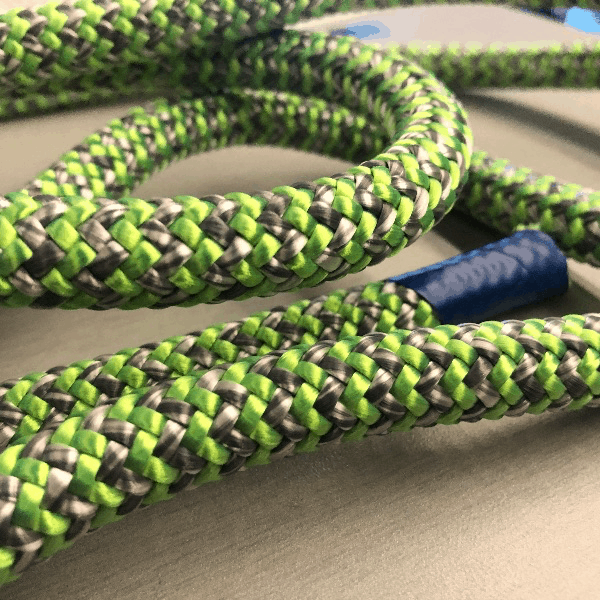

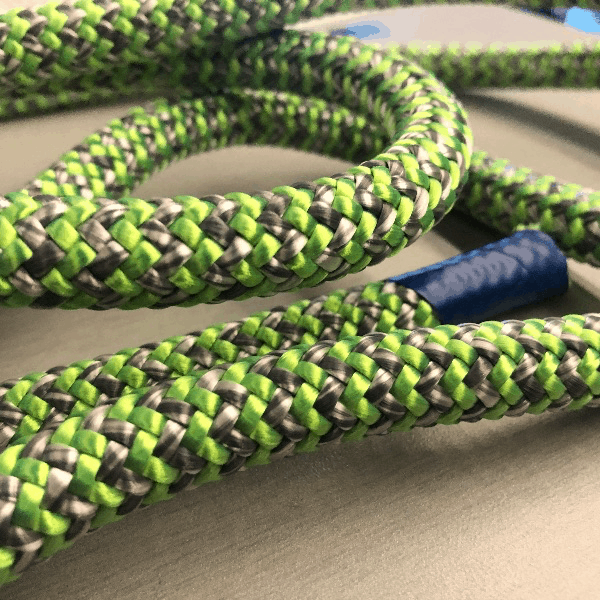

Samson rope have now taken over making the 'Poison Ivy' series of rope for Sherril Tree, the range includes 'Midnight Ivy', 'Tango Ivy' and 'Silver Ivy'.The reason for the change from Yale to Samson is allegedly that Samson will be able to keep up with the demand for this product.

Petzl also released 2 ropes under their brand this year, the Petzl Flowand Petzl Control. The Petzl Flow is 11.6 mm with 2.8% elongation, and the Petzl Control is 12.5mm with 3.1% elongation. Both ropes have a 24 strand cover and meet CE EN 1891 type A, ANSI Z133.

Petzl also released 2 ropes under their brand this year, the Petzl Flowand Petzl Control. The Petzl Flow is 11.6 mm with 2.8% elongation, and the Petzl Control is 12.5mm with 3.1% elongation. Both ropes have a 24 strand cover and meet CE EN 1891 type A, ANSI Z133.The reason Petzl chose this Cousin-Trestec rope to sell under their brand is because the splice can be passed through the Zigzag and works well in conjunction with this mechanical device, so it combines perfectly with this Petzl product.

DMM also released some new pieces of hardware to their arborist range of products, including the new 'Hitch climber Eccentric' and new compact swivels .

Business news

Sherrill Inc. acquires Sterling rope company

Sherrill Inc., NC-based arborist and climbing gear company, this year acquired ME-based life safety rope manufacturer Sterling Rope Company Inc.Sterling is an industry leading rope manufacturer who has been supplying climbers, climbing gyms, arborists, search and rescue personnel, fire departments, industrial safety and the military for over 25 years.

Birch Lake Investments Ltd. Acquires ISC (International Safety Components Ltd.)

ISC said "The transfer of ownership provides Denny Moorhouse with a move into retirement after more than 50 years of industry-leading innovations in height safety devices. As a young adult, Moorhouse developed a passion for mountain climbing which led him to become a climbing instructor in the early 1960s. His enthusiasm for climbing continued to grow, and he soon looked for other ways to be involved in the industry. In 1966, Moorhouse established Clogwyn Climbing Gear Ltd, where he began manufacturing innovative climbing safety gear that eventually led to industrial safety products and what is now ISC.

Birch Lake Investments’ acquisition of ISC fulfills Moorhouse’s desire to see ISC remain an independent company."

2019 competitions

Aerial resuce challenge by Wesspur

Wesspur held their first ever Aerial rescue Challenge event. This event was the brainchild of Dave Stice. The competition focused heavily on patient care in each event, using live patients, fake blood and sequestered competitors in order to give the most real life situation possible. The events also required all climbers to be permanently secured on 2 ropes in an attempt to educate each competitor in 2 rope climbing techniques along with integrating some SPRAT techniques. Word on the grapevine is, there will be more of these events in the future.

Champ Champ Scott Forrest!!!

August 2019 in Knoxville, TN, Scott Forrest won the ITCC for the fourth time. Josephine Hedger also took the women's title for a fourth time.Later in the year in mid October, RedBull held their 'Branched out' competition in Kapunda, SA, Australia with 150 competitions. Scott Forrest put on some amazing climbs to take the winners trophy at the 3rd RedBull Branched out.

Safety standards and regulations news

It has long been looming, and over the last year or so the talk of climbing permanently attached to two separate climbing systems has become more common.The United Kingdom have become the first to make this system standard within arboriculture, and has been implemented by the 'Health and Safety Executive' (H.S.E.) The below paragraphs are taken from the Arboricultural association website;

Following the announcement in the Autumn issue of the ARB Magazine (issue 186, page 7) that the HSE is now requiring full compliance with the Work at Height Regulations in relation to tree climbing operations, there has been much discussion and debate.

The relevant section of the Regulations is Schedule 5, which addresses requirements for personal fall protection systems. See www.legislation.gov.uk/uksi/2005/735/schedule/5. The HSE has observed that some aspects of these requirements have been largely ignored by many climbing arborists, and that current training and assessment standards do not adequately address these issues.

The HSE has provided details of reported fall from height accidents for a one-year period, which can be viewed on the AA’s website: www.trees.org.uk/2ropes-incidents. The background to this wider issue can be viewed here: www.trees.org.uk/2ropes.

Final thoughts

Let's all see a safe end to 2019. For our families, friends and ourselves let's continue in the goal to be safer at work and help keep our colleagues safe, after all we work as a team, we should work to be safer as a team.Happy holidays, Merry Christmas and a happy new year to all. Wishing you and your family a happy and healthy end to 2019 and into 2020.

Changing lives one tree at a time

By Dan Holliday |

Blog post written by: David Anderson (Canopy watch international)

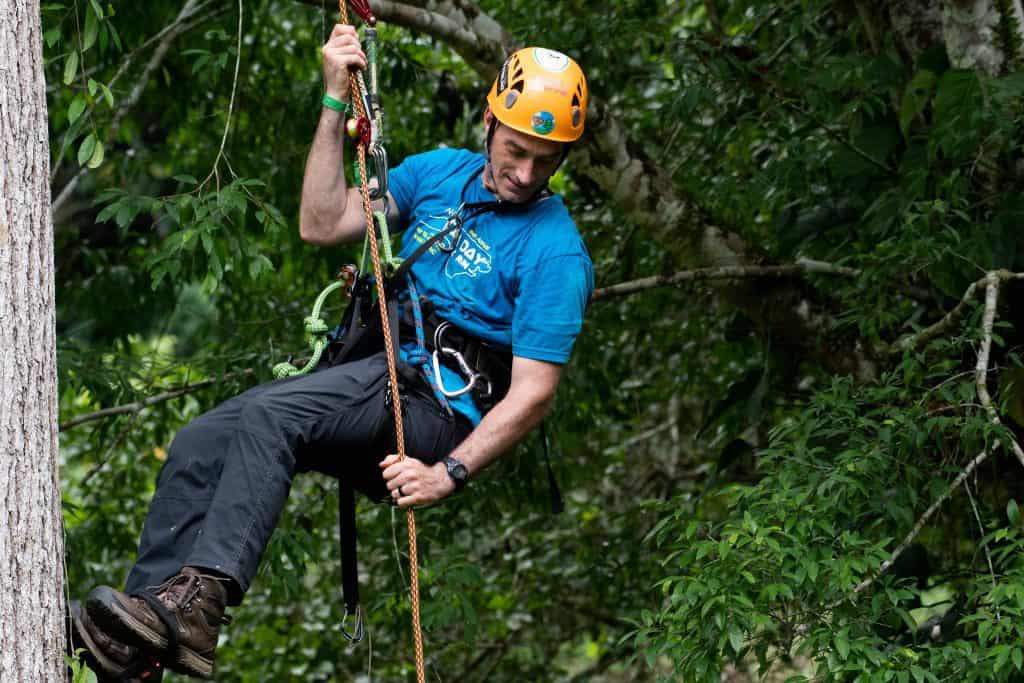

Trepadores every one. Hardy climbers and instructors Discovering the Canopy the Colombia way. Photo © Felipe Barrera

Trepadores every one. Hardy climbers and instructors Discovering the Canopy the Colombia way. Photo © Felipe Barrera“clap . . . clap . . . clap-clap-clap

clap . . . clap . . . clap-clap-clap”

The sound of clapping hands splashing through the tropical forest of Colombia, growing in volume, bouncing off tree trunks and leaves,

“clap . . . clap . . . clap-clap-clap”

louder and louder, until the refrain reaches a crescendo, joined by a call: “UNO . . . DOS . . . TRES . . . ¡TREPADORES!” 24 voices shouting in unison “¡CLIMBERS!”

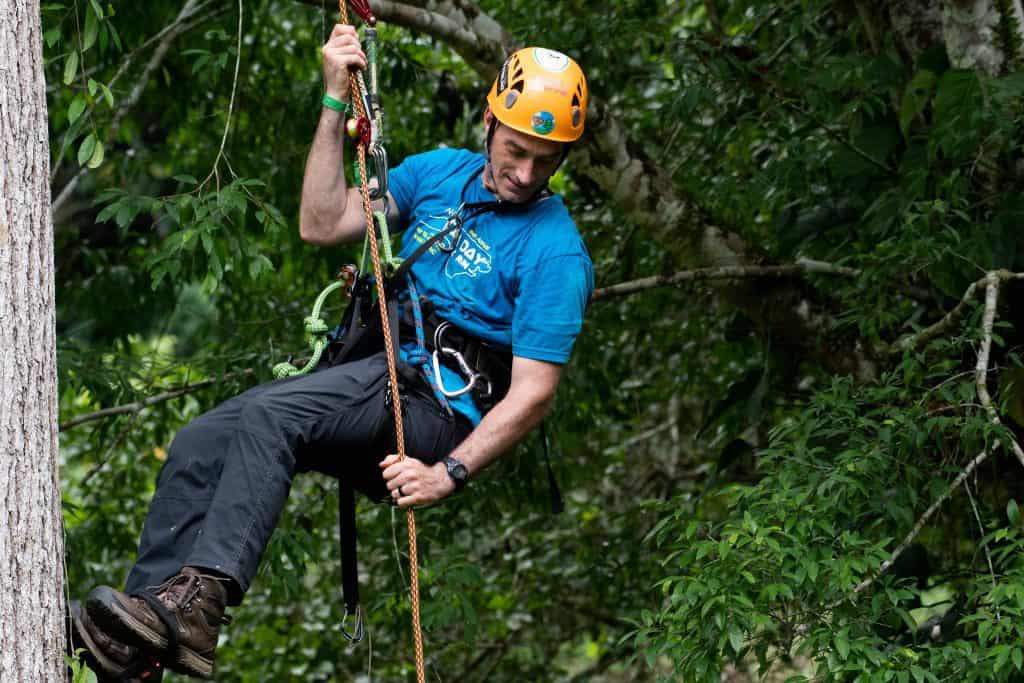

And so begins a typical day for the decidedly atypical Descubriendo el Dosel 2019 (Discovering the Canopy 2019), our most ambitious climber training ever. In a burst of applause, 19 students and four instructors spread into the forest, helmets on heads, ropes in hands, in search of trees to climb and new skills to learn and master.

During a steamy, sunny week at the Río Claro Nature Reserve in Colombia, we have a big target ahead of us: Turn 19 biologists from Latin America--novice climbers every one—into competent and confident tree climbers, ready to return home to ascend their own local forests for conservation research that no one else is doing. It’s a part of our mission to bring canopy access—and canopy conservation—to the world, one climber and one country at a time.

Climber training is a beautiful thing. Every tree is a riddle to solve, every technique and piece of equipment is new. Men and women who spend their lives walking the ground and who normally consider heights a dangerous thing are now asked to hang their lives on ropes that have the diameter of a dime. Below each tree two biologists sporting bright yellow Petzl helmets shout encouragement and advice to their colleagues nervously making their way up, down, and around lush tropical trees. Instructors on Yale ropes keep an eye on technical details, watching for safety every second. By opening the minds of students, and leading them to unlock problems for themselves, they will be prepared for the careers to come when no one will be there to explain what to do next or to check on their safety.

The essence of climber training: students on rope, in trees, learning from each other in challenges they couldn’t have predicted. Photo © Juan Carlos Rivas.

The essence of climber training: students on rope, in trees, learning from each other in challenges they couldn’t have predicted. Photo © Juan Carlos Rivas.We are here to teach and learn. Every day there are new pieces of equipment that are introduced, their proper and improper uses explained. How do you arm a climbing system to get you up a rope efficiently and safely? Where do you attach ropes to your harness when you’re climbing vs. when securing your position to a trunk or branch? Hands, arms, legs all repeat new motions so many times that they start to react with muscle memory that didn’t exist a week earler, until a motion that felt unnatural and clumsy on Day 1 happens smoothly and instinctively on Day 5. And always there are the trees. How do you put a climbing rope 100 feet into a tree while standing on the ground? How do you move across the entire width of a tree while suspended on a rope? How would you go out on a branch, then lock into your position so you can install a camera trap without swinging out of place? These images are textbook definitions of training.

Yet we work on something more fundamental than equipment function and muscle memory: We work on the heart. New climbers are trusting their lives to us every day.“Walk out on that branch 20 feet. Trust me.” More importantly, minute by minute, hour by hour, we build their trust in each other and in themselves, for preparation when we’re gone. “Swing your body from this tree to that one and stay put. Trust yourself.” Conquering fear with trust builds self confidence and changes lives. It takes the old you and makes someone who is stronger and wiser, who is able to do more and better work. The hand clap that calls all climbers back to base before and after every exercise? It’s no accident. It takes the role of authority, and of trust, from the hands of instructors and puts it directly into the hands of the students. Quite simply, it takes a group of students and instructors and makes us family.

Textbook photo for the definition of “climber training”: Luz Adriana Molina limbwalking and pushing beyond her limits. Photo © David L. Anderson

Textbook photo for the definition of “climber training”: Luz Adriana Molina limbwalking and pushing beyond her limits. Photo © David L. AndersonIf there is one lesson that came out of this grand experience it is this: Dream Big. The idea behind Descubriendo el Dosel 2019 was grand and big, improbable if not impossible. We sought no less than to hand the reigns of conservation science over to local biologists who live and breath and work and raise families in imperiled forests.

Family. It makes us stronger and better, and is what Descubriendo el Dosel is all about. Photo © Felipe Barrera.

Family. It makes us stronger and better, and is what Descubriendo el Dosel is all about. Photo © Felipe Barrera.So Lesson #2 follows: When you want to dream big, take your friends along. This training was a success because of friends and partners who were absolutely critical to this effort. First and foremost, Fundación Alianza Natural, (LINK) a non-profit conservation organization in Colombia, was the official host of this event and did all the in-country organizing and prep. Petzl Foundation(LINK) came in early as our official Hardware Sponsor, donating helmets, harnesses, carabiners, lanyards, and a long list of vital equipment. Yale Cordage(LINK) was the event’s official Software Sponsor, donating miles of rope, literally.

No dream is too big to be impossible. Photo © Juan Carlos Rivas

No dream is too big to be impossible. Photo © Juan Carlos RivasOne climber, one tree, one forest, one planet at a time. This is the height to which we ascended. THANK YOU.

For more about Descubriendo el Dosel 2019,check out the hashtags #dosel2019 or #descubriendoeldosel on social media, or visit the event’s Flickr page.

Want to help us change lives in the next round? Go to the webpage for Canopy Watch and contact us. We can always use more friends and partners.

Petzl Foundation came up big as our official Hardware Sponsor.

All this pretty equipment rewrote the history of canopy research in Latin America and the changes lives of the lucky biologists getting to use it. Photo © Juan Carlos Rivas.

Petzl Foundation came up big as our official Hardware Sponsor.

All this pretty equipment rewrote the history of canopy research in Latin America and the changes lives of the lucky biologists getting to use it. Photo © Juan Carlos Rivas.SUR Company(LINK) headed by Javier Urueña in Bogotá, and Orozco y Cia.(LINK) headed by Hernando Orozco in Medellín, made it possible to ship all that expensive gear to Colombia. The Peregrine Fund(LINK) is a conservation non-profit in the United States that believes so strongly in changing lives and building local capacity that they sponsored my time and many of the grant proposals for the project. The wonderful people at Río Claro Nature Reserve(LINK) discounted our food and lodging, true, but the beauty of the natural setting added a tangible flavor to our success. The good will from so many people was an avalanche. We received so many valuable donations from Nick Bonner at TreeStuff, SherrillTree, NuGreen Store, Kevin Bingham at Singing Tree, DMM Wales, WesSpur Tree, that brought trees to the scientists and put scientists in the trees. And last but not least, it takes cash to offer an event like this. The Rufford Foundation(LINK) trusted us and believed in our mission. To each of you, a most special applause from our family: CLAP . . . CLAP . . . CLAP-CLAP-CLAP.

Lead Instructor, mentor, friend – Jamz Luce conducting the choir.

Lead Instructor, mentor, friend – Jamz Luce conducting the choir.  Patrick Brandt, you radiate calmness and authority. We were all better for your presence.

Patrick Brandt, you radiate calmness and authority. We were all better for your presence.  Emmett Lawrence put his heart way deep into this training. I’m glad you were there.

Emmett Lawrence put his heart way deep into this training. I’m glad you were there.  Juan Carlos Rivas was the eyes and brain behind so many of our photos. Photo © Juan Carlos Rivas.

Juan Carlos Rivas was the eyes and brain behind so many of our photos. Photo © Juan Carlos Rivas.  Laín Garzón of SUR Company was a strong and quiet presence all week. Gracias por acompañarnos.

Laín Garzón of SUR Company was a strong and quiet presence all week. Gracias por acompañarnos.Life support equipment, don’t be so blasé

By Ryan Senechal |

I arrived to check on a contractor’s progress on a tree removal and was drawn immediately to what appeared to be an improvised mechanical advantage system (for tree pulling) laying on the ground beside a felled spar consisting of a collection of climbing equipment, and some gear that could easily be confused as rigging or climbing equipment. A friction saver used as an anchor, a climbing rope reeved through a couple of hitch climber pulleys, a rigging block, two hitch cords, etc. The site supervisor assured me that they didn’t have to pull very hard to get the tree over (for what it’s worth). I couldn’t decide what was the best way to address my concerns because my gut was telling me that what I observed had deeper roots than the decisions of one tree worker. The problem? Climbing components that are configured for rigging tasks without a second thought, and with no consideration of where those components might end up next.

The source(s) of the problem is complex of course, combining:

- - A product development curve that has been fast moving and driven by a relatively small group of highly technical gearheads, and competition climbers.

- - Manufacturer product training programs that consist of a single international manufacturer representative presenting short sessions at major conferences and at a handful of workshops world-wide.

- - Introduction to products from your buddy that knows lots about gear, YouTube, or worse.

- - An inherent skepticism about gear cost versus benefits by supervisors or owners (that may ormay not be familiar with the gear being requested) or a negative perception of how gearpurchases might change work productivity.

- - A reluctance by climbers to spend money on gear due to the high cost or because the productsthey know are no longer produced.

- - Rushed apprenticeship periods or an inability to pair apprentices to mentors.

- - Supervision used rarely and reactively, rather than frequently and proactively.

- - A reluctance by supervisors or owners to spend money on gear due to past experiences ofequipment abuse, misuse, non-use, or loss.

- - An insistence by experienced workers that learned in gear-restrictive environments to passsimilar expectations along to new workers

- - A lack of understanding of how damage occurs to life supporting equipment

- - Casual attitudes toward risk to self and others

- - Omitted equipment incidents or close call accounts for fear of reprisal

- - Company provided climbing equipment programs that reassign used items (as personnel comeand go) without effectively logging entry of service, inspections, or reporting potential eventswhere Safe Working Loads/Working Load Limits have been exceeded.

- - The need to do physical work, with knowledge of tools that reduce physical and mentaldemands on a worker or workers.

Today’s fit-for-purpose tree climbing equipment is exceptionally well-built in terms of durability, wear indicators, and safety margins. Cases of equipment failure are less commonly seen in incident statistics, but less common does not mean uncommon. Three of my colleagues have fallen on account of equipment failure – one of whom did not survive. Many experienced climbers that keep themselves current on PPE inspection have direct experience removing gear from another climber that was down to its literal last threads. These are not gear problems, but gear-user problems (in most cases).

What do we do about it? The first step is examining your own workplace for conditions like those I’ve just bullet pointed. You could start by picking any tree truck at your workplace and pulling loose gear off it for examination. Tree trucks that have loose, unassigned climbing equipment such as climbing ropes, friction savers, carabiners or micropulleys indicates that there may be a problem. Knowing what you do, do you feel comfortable using those mysterious items based on a visual inspection alone, and is it reasonable to reassign that gear with origins or service history unknown? This is one of the main reasons why I buy my own gear, why I don’t loan my gear unless I am directly participating in the operation, and why I do my absolute best to account for each item after every use and ensure each piece of gear goes to its happy home when work is done. Remembering all the gear you have and when it entered service is no easy feat. Having all your gear recorded on an inventory makes for easy inspections.

The harder tasks won’t be solved in the short term and require those of us in positions of mentoring to think carefully about the values and lessons we’re sharing. If you find yourself frustrated by new equipment entering the workplace or how those tools might change how tasks are completed, a bit of money to secure time with professional industry trainers/product experts can help the entire crew learn in a safe setting improving familiarity, competency and productivity all at once across the workplace. If you find yourself deeply skeptical on the benefits of the latest tech to hit the tree gear showroom, you’re not alone. If you’re determined to use modern tools as a workplace cultural incompatibility indicator, then you most definitely have your work cut out for you on recruiting and retraining. If you swear it’s the last, last, last time you’ll ever buy an expensive item for a climber because it’s been lost yet again, you could consider talking to some of your colleagues in the tree business for other ideas to encourage gear appreciation and accountability. Restricting climbers from the gear they like to use or need to use will have compounding effects starting with diminishing morale for the climber and eventually their coworkers (precursors to flight risk, property damage risk, or injury risk). Yes, there are abusers, but amnesty is in unnecessarily short supply considering what those tools deliver in productivity, ergonomics and safety.

There’s no need to scream & shout!

By Dan Holliday |

Having been in the tree care business for 13 years I have seen huge progressions in the Arboricultural industry when it comes to equipment. From decay detection equipment, to non-invasive bracing equipment, improved power tools and a huge amount of new and innovative climbing tools and equipment. So why is it, that in 2016, in this era of technology, clear communication tools are only just beginning to creep into our industry.

In such a high-risk industry where we are reading about incidents almost daily through the various channels of media, why have we still not identified Bluetooth communication as a must have piece of equipment for daily use among our crews. Communication is one of the most important safety factors in our day to day business, yet when talking about safety and incidents, as an industry we seem to accept that screaming and shouting single word commands at the top of our voice is just part of this business.

In such a high-risk industry where we are reading about incidents almost daily through the various channels of media, why have we still not identified Bluetooth communication as a must have piece of equipment for daily use among our crews. Communication is one of the most important safety factors in our day to day business, yet when talking about safety and incidents, as an industry we seem to accept that screaming and shouting single word commands at the top of our voice is just part of this business.

Let me tell you, as someone who has used these Bluetooth headsets, that is not the case, screaming and shouting is stressful and frustrating, it limits the message you are trying to get across and it looks and sounds so unprofessional to onlookers, in comparison to using a head set that is built into your hardhat.

My experience with 2 way radio systems 10 years ago

My experience with 2 way radio systems 10 years ago

I’ll take you back to the first ever crane job that I was the climber for, this was about 3 years into my career as an arborist. My boss had gone out and bought a pair of 2-way radios so that I could communicate with him and the crane operator clearly as they may struggle to see me and hear me, and good communication was going to be imperative to a safe and successful job without any injuries. The tree was a Giant Sequoia and we would remove it in approx 8 pieces (if my memory serves me correctly), with the branches still attached. This meant that there would be clear communication leading up to the cut and then a break while the piece was craned away and placed on the ground. This meant that the 2-way radio was adequate for this particular job, because as the climber, there were natural breaks between cuts, and the crane would be doing the hard work. Why is it though, a crane job warrants this kind of communication, yet undertaking a removal on the same or a similar tree without the aid of a crane would be done without this kind of communication?

Using the Sena SMH10R bluetooth system

Using the Sena SMH10R bluetooth system

After using the Sena SMH10R Bluetooth headsets on a variety of tree pruning and removal job sites, it soon became apparent that this kind of headset should become as common as a chainsaw on the job site. Instantly, all the guys on the jobsite knew what was going on at all times (this model can accommodate 4 people). As a climber it is great because you can explain things to your crew as you are climbing around the tree (you don’t need to stop and shout to the crew). You can let them know you need some rigging equipment and which components, if you need your saw fueling, or even if the crew is chipping (they can still hear you) and you drop your handsaw, you still have clear communication. These examples that I have given are quite obvious that make a huge difference, but it’s the little things that you would never think about until you use this type of communication system that really cement this as a must have piece of kit. For example, if you keep your helmet on while reversing the truck and chipper you can get more precise direction from your spotter. When you are on a job site and you are pruning for your client’s view, you can have a crewmember stand with the client and communicate which branches they would like removed, you can then communicate back through your crew and give your thoughts on the pruning.

It’s the small things

It’s the small thingsOne of the biggest factors from using these headsets is how the work environment becomes way more enjoyable, because nobody has to raise their voice and get annoyed due to their message not getting across, no screaming until you become red in the face and veins start bursting, and in-between all safety calls and gear requests you can shoot the shit with the crew.

You can even sync the headset to you phone to make and receive calls, and when you have those boring hedging jobs you can play some music from your phone to keep you entertained all day long.

Increase the safety on your work site

Increase the safety on your work siteIf you often undertake work in locations where there are many people around such as street tree pruning, local school contracts, apartment buildings etc… Then your site safety must be at its best because with any lack in concentration and site control a member of the public can be hit by a branch or a stub. These Bluetooth headsets increase site safety a huge amount, because it allows members of the ground crew to clearly communicate with the climber of any members of the public approaching, and the ground crew will be sure that the climber heard with a simple acknowledgement. The climber sometimes will have a much better view of the area and can alert the ground staff to on coming people that may need to be redirected, or communicate some traffic control that is required. With all the added communication via the headsets makes for a much safer and more efficient work site which should always be of the highest priority. The new TuffTalk headset

SENA have also just launched a new line of headsets call ‘TuffTalk’. The TuffTalk system by Sena is a set of ear muffs design by Sena that has the whole system integrated into the ear muff itself, meaning no installation time and easily clip the system to any helmet and remove it when not required. It is as simple as switching out a pair of earmuffs in your hard hat.

This system/design is slightly more exposed for the tree climber, having the stiff microphone boom sticking out, and having the control buttons on the ear muffs that can be accidentally pressed while climbing through the canopy of a tree.

I am a huge fan of my Husqvarna ear defenders before they snap down onto my ears making a great seal. The Sena uses the same system as the Peltor ear muff with two thin rods of metal coming from the mounting and personally they don’t clamp down on my ears as much as the Husqvarna ones do, but if you use Peltor/3M/Stihl muffs the Sena is the same system as these. To Conclude

If you haven’t tried these Bluetooth headsets you must! Trust me you won’t regret it!

They make work more enjoyable, much less stressful, everyone on the crew knows what’s happening, create a safer work environment and make you appear much more professional to your clients and to onlookers. Once you make these part of everyday life you’ll think how ridiculous it was with all that screaming and shouting.

To view the range of awesome headsets sold by SENA visit their website. You can also order these products through Wesspur (US), TreeStuff (US) and TreeNorth Industries (Canada) or at your local arborist supply stores.

New WorkSafe BC Arborist Regulations for British Columbia

by

WorkSafe BC has approved proposed amendments to Part 26: Forestry Operations to include a subsection for Arborist Activities. There is a four month transition from the Board of Director’s approval of this amendment to when it becomes law on December 1st, 2021. You can review the changes here: https://www.worksafebc.com/en/law-policy/public-hearings-consultations/closed-public-hearings-and-consultations/bod-approves-2020-and-2021-amendments-ohsr-may-2021

Will this have implications for your workplace and more directly your own work practices? Yes. Why are these regulations being adopted? Industry has not effectively addressed the rate of fatal and severe injury incidents to workers in the province, and the high insurance premiums or non-compliance penalties Tree Services pay haven’t deterred dominant behaviours. Through consultations with industry leaders representing different segments of the industry, WorkSafe BC has implemented regulations that will be an adjustment for small and large businesses alike.

Source: WorkSafe BC Tree Services Classification Unit Description and Rates

Reactions to these regulatory changes were mixed during the consultation period; resistance from some vocal industry participants targeted time and money. Yes, initially these changes will cost time and money. The playing field is about to be legally levelled with a recipe that promises to address our industry’s high rate of incidents. We can anticipate some will opt out of compliance although WorkSafe BC has assured us that Prevention Officers will be provided training ahead of adoption (December 1st, 2021) and that Tree Services will be a focal point for site inspections.

Key themes of the new Arborist Activities amendment to Part 26 of WorkSafe BC’s Occupational Health and Safety Regulation include definitions, arborist activities planning, tree climbing equipment, tree climbing planning, and tree climbing procedures. The entire part has been framed as a non-prescriptive, best practices approach which will require some legwork for workplaces to demonstrate compliance and due diligence. For the many Arborists working in BC having been trained outside of the province or out of the country, this new regulation could improve working conditions as credentials, training, education and experience from outside of the province becomes recognized. For example, OHSR Part 26.1: Definitions describes the following:

“qualified arborist”

means a person who

(c) has, as appropriate to the work being done, knowledge, through training or a combination of education and training, of and experience

Note that there is no measurement of experience, knowledge or training, or examples given of what education might be “appropriate to the work being done”. To paraphrase, Qualified Arborist means a person who has demonstrated beyond a reasonable doubt to a panel of occupational health and safety peers (including industry subject matter experts) that the person is competent to perform the task they have been assigned to complete. This is not simply tree climbing, but most scenarios a tree climber is likely to encounter. Third party industry trainers and credentialing organizations have an important role in supporting workers to demonstrate compliance with this definition of Qualified, although internal workplace training may suffice so long as the trainer is Qualified and the training provided meets industry standards/best practices.

Flexibility enabled through this non-prescriptive approach can lead to confusion and frustration, and this is where collaboration with your regional tree care community partners can be quite helpful. One source of confusion and handwringing through the consultation phase of this amendment was related to Part 26.12.0.3 which provides context for inspections of trees and creation of a tree climbing plan, and the requirement for the documenting of that plan. Imaginations ran wild on this section, with suggestions that this added time tax burden would drive owners out of business. While there will undoubtedly be some time cost associated with completion of a site level hazard assessment, our industry’s safety performance continues to lag behind other industries that have taken strides to measurably reduce rates of incidents. A document alone offers no physical protection from harm, but the process of crew participation in a site level hazard assessment has time and again proven its value in reducing incidents, in preparing workers to respond quickly and effectively in emergencies, and to support an improved workplace safety culture.

Tree workers transitioning into compliance with this new regulation can take a few important steps to help make this process relatively painless so we can get to the benefits sooner (fewer workers being hurt or killed on the job):

Let your employer know about these regulatory changes and offer your support in reaching compliance. Although efforts have been made to spread the word about this new regulation, many workplaces will have no idea of its existence. Employers do have a legal obligation to comply with the regulation although early adoption will only be possible if the employer is made aware of the new regulation and the workplace works together to implement required changes.

Create a PPE inspection spreadsheet. Documenting your fall protection and rigging equipment is one simple task that can address multiple requirements under Part 26.12.06 Tree-climbing equipment. The ISA ITCC has produced a PDF inspection formwith a simple layout that could be recreated unique to your workplace. From here on out, future gear purchases should be fit for the purpose of industrial tree climbing and certified/labeled with traceable product information. There must be technical information for the product that addresses inspection and retirement criteria, configuration, operating limits and load ratings, and these should be available to the gear owner in hard copy or digital format.

Make time with your crew to talk about the hazards, and document them before you start working. These are hazards specific to your work location and the tree(s) directly or indirectly involved in your work. For every hazard, identify controls you will put in place that will allow the entire crew to work safely around those hazards. Discuss the loads anticipated of required tree work on climbing and rigging anchors and plan systems to minimize the potential for overloading the structure or equipment. Finally, plan for emergencies unique to the conditions you are working in to enable a quick and effective response. All of this can be quickly captured on a tailgate, tailboard, site level hazard assessment, jobsite safety assessment, etc. You can ask nicely for a copy of a tailgate from one of your industry partners and modify it for your own workplace.

Strive for credentials or qualifications. Within the province of BC there is lots to choose from to validate your knowledge, skills, training and experience through qualifications and credentials. Qualifications that set a high benchmark through prerequisites and written/performance skills exams are valuable, as are credentials that set continuing education renewal requirements. Here are some examples:

ITA BC Arborist Technician Certificate of QualificationITA BC Climbing Arborist Certificate of Qualification

ISA Certified Treeworker Climber Specialist

ISA Certified Arborist

ISA Tree Risk Assessment Qualification

TCIA Certified Treecare Safety Professional

Keep your resume up to date. Any previous training you’ve received from beyond your workplace should be noted down to demonstrate your commitment to professional development. This can include webinars, conferences, workshops, courses and climbing competitions. Previous work experience is also valuable here, along with your roles and estimated hours performing common tasks. Restricted trades require a Qualified supervisor to sign off on an apprentice’s hours for specific tasks if the apprentice wishes to one day reach qualification. Our trade is not restricted at this time, but we can definitely do a better job of tracking our hours on rope, rigging, on a saw, or in a bucket truck as a starting point.

Check to see if your work practices meet the standard. Safe work procedures should be documented and immediately available to workers in the field. These can be developed in house, and should reflect objective criteria (such as ANSI Z133 for Arboricultural Operations) wherever possible. If your methods of approaching common tasks are not recognized by your industry partners or have been determined to be unacceptable for safety reasons, be prepared to defend your rationale if you want to continue using this method.

Thinking of this regulation as more of a carrot and less of a stick is to everyone’s benefit. As workplaces transition to reach this new standard set, fewer lost time injury incidents, fewer fatal incidents, and reduced insurance premiums will result. A little further down the road we might find reduced stigma associated with dangers of the tree care profession, longer careers and better quality of life for Arborists, and improved outcomes in recruiting new workers.

Have specific questions about the new Arborist Activities regulations? Let’s hear them.

Skills improve my efficiency; efficiency improve my skills!

by

Efficiency doesn’t seem like a sexy or glamorous subject when compared to discussing the latest and greatest climbing products or machinery on the market. But, for me at least, the new, shiny, expensive gear or the latest machinery I keep looking at in the Arbor magazines all play a part in improving my efficiency practices. Think about it – would you still buy a new ascender that was the coolest color, the nicest shape and had the best name, if you heard that it dragged badly on the rope causing a lot of friction and making your ascent more difficult?

With this prior knowledge, probably not.

Efficiency is accomplishing a task in the minimum amount of time with the least amount of energy expended.

In recent years, efficiency has become my favorite topic. It is something I focus on everyday across every aspect of my job. The more I focus on efficiency, the more I understand where techniques and systems can be improved upon. I realized that the way I work (for example, my climbing techniques) can improve much more quickly if I understand what I am doing, why I do certain things, and if I take time to analyze. This allows me to make major or minor tweaks with the aim to improve efficiencies.

Implementing efficient practices

To successfully implement efficient practices involves a mixture of planning, common sense and experience. If I am to complete a task I have never done before, I use the follow method: 1) I make a plan that I believe makes the most sense, in this particular situation; 2) I select the best equipment for the task; 3) I delegate relevant tasks to my crew who are most capable in these various roles; and

- complete the smaller tasks in a sequence that makes the most sense for accomplishing the job.

Once the job is complete, I can then analyze and take note of what worked well, what went wrong, and what worked but what can be improved upon for future jobs of this nature. It is this process of analyzing and being aware of my systems that allow me to become more efficient as each time I take on a similar task my efficiencies should improve.

The process of understanding and analyzing systems (climbing techniques, job planning, rigging setups, etc.) are key. If I didn’t pay attention to how things worked, I’d continue to use the same methods which would result in my evolution as an arborist becoming stagnant and I would miss opportunities to implement new, more suitable systems.

Looking at the bigger picture of an arborist’s career, implementing efficiency goals will result in less short- and long-term fatigue, career longevity, reduced chance of long-term muscle injuries, stress reduction and a constant learning curve as you evolve your skills.

Improving efficiency through experience

Recently, I and my team member, Conor, were tasked to remove a very tall, dead Hemlock tree. The location of the tree and gradient around the tree meant it would not be a straight forward and easy removal. There were multiple large trees nearby, so the best and most effective plan I could come up with was to set a rope between two live trees and install the rigging block in the middle of the rope that spanned the gap between these trees. We would then rig the Hemlock off this point which would make quite a large swing, hopefully, resulting in the pieces being rigged down into the flat driveway of the property. We used a rigging hub on the end of the rigging line as we needed to attach multiple ropes (a haul line for me as the climber, a tag line for Conor, the rigging line, and the webbing sling). A couple of pieces got hung up in some smaller trees close to the ground, but the job went well on the whole.

Conor, has only been in the industry for 3-4 years and he had never used or seen this exact setup and was unsure of how everything would work. Being a quick learner and problem solver, Conor gained a full understanding of the system and figured out the adjustments required to prevent issues by the time the job was complete. Conor will now take the experience from this job and be fully aware of all aspects of the rigging technique and where potential problems may lie when we next use this system. Thus, he is now a better crew member as a result of this thoughtful approach.

Key considerations

When considering efficiencies for an entire job or a singular technique, these are the key elements that I think about:

- Make a plan and be willing to make adjustments to improve efficiency.

- Try not to allow pressure to cause me to rush (rushing/panicking can result in poor decision making, not working with a systematic approach and not using the right equipment, or worse cause an injury).

- Choose the best tool or tools for the job.

- Select the best technique for the task, allocate jobs to crew members for completion in an order that makes sense.

- Share ideas and experiences with team members: discuss my favorite and least favorite techniques, talk about jobs that went well and those that did not go as well, and list the reasons why for each experience.

Saving time and energy with rigging systems

In the right situation, rigging systems can be a huge time and energy saver. Creating the most complex system for a specific scenario that may require a 2-hour setup are still more efficient than without this system. Moving wood without much effort to an end location, rather than using all manpower, can be absolutely amazing. For me, I always weigh the following options in my thinking process: How long will it take to set up the rigging components? How long do I estimate the job to take once rigging is set? How long

would the job take without this rigging or setup? If I feel like the rigging option will take the same amount of time or be quicker, I will always choose rigging. The reason for this is because if I can move wood in a way that reduces manpower and fatigue then I would prefer to save the crew’s the energy if I can complete the job in the same amount of time.

My obsession with efficiency!

The biggest gains I have made in the last 3-4 years relating to my tree climbing skills have come from my obsession with efficiency. Instead of thinking about my next move or task, I think about multiple tasks ahead of me. For example, my work positioning while using a chainsaw – I now focus on choosing the best lanyard configuration for the work, select the optimum lanyard location to make the maximum amount of cuts while not having to change lanyard position multiple times, and maintain a safe, comfortable position for cutting. Compare this to only looking at the next branch to remove or prune, putting on my lanyard, and then removing it after that one task. Doing that action for 8 limbs will eat into my time when I could select one lanyard position that allows me to reach all 8 limbs.

Another climbing-based technique I utilize to improve efficiency is to make undercuts on multiple branches with a chainsaw, then doing the top cuts using a handsaw when I need control. This maximizes the use of the chainsaw first to save energy.

Don’t let stubbornness stifle efficiency!

I have owned a battery powered, top handled chainsaw for a couple of years and love all the benefits that come from using it which I believe improve efficiencies in various capacities. There have been times, however, when I have continued to use the saw during removals for too long. As the wood gets too large, the saw begins to struggle. I then use more force which causes wear and tear on a tool that is not designed for purpose,all because I am enjoying my new favorite tool and didn’t allow myself to recognize when it was time to switch it out for something more suitable and efficient.

Good communication to create seamless operations

Another great form of efficiency is through clear communication. In recent years, Bluetooth communication headsets have become available for use in arborist helmets and have made a huge impact on my daily worksites. Communication has become so much easier while working. The crew can have a full conversation at a normal volume and tone, instead of the well-known screaming from high in a tree with single word demands. Even if those short instructions are said with the kindest of intent, they come across aggressive, hurried and always missing reasoning around the request. Instead, asking for equipment through a headset, (e.g. specific rigging equipment), you can ask for the exact components you require, where they are located, how you would like them configured and what your plan is.

If you are working with a crew of 3 or 4 people all wearing headsets, even when your conversation might only be with one member of the crew, the other people in your team will hear the entire dialogue. This means the whole team is in sync with how the jobsite is running, which roles to take on, and what to expect. If you have never used these headsets on a jobsite, hopefully, this short example is a brief insight into how useful and efficient headsets are, but you will really never know the full benefit until you actually use them.

Efficiency is so important within the tree service industry, the more we are all aware of each and every aspect of our day to day tasks and how they can improve, the better, more fun, more enjoyable, safer, and longer our careers will become.

2019 – A year in review for climbing arborists

by

2019 has been a very interesting year in arboriculture, there has been new equipment launched into the market, people are constantly experimenting with new climbing techniques to improve efficiency and there has been a huge shift in regulations within the U.K. Arb industry.

New equipment released in 2019

The Petzl Chicane was released early in 2019. Petzl has designed the Chicane to be used in conjunction with the Zigzag for stationary rope system climbing. The Chicane adds friction above the Zigzag to allow for smooth operation, the idea coming from the way the rope wrench adds friction above a hitch. The Chicane/zigzag combo has had rave reviews, although Petzl are still getting heat from diehard rope wrench fans.

Rock Exotica finally released the much anticipated Akimbo. The Akimbo is a mechanical device that can be used both in stationary and moving rope systems (although primarily for SRS). The buzz for the release of the Akimbo was huge, and it seems to be flying off the shelves like hotcakes, although it has received mixed reviews across the board.

Samson rope have now taken over making the ‘Poison Ivy’ series of rope for Sherril Tree, the range includes ‘Midnight Ivy’, ‘Tango Ivy’ and ‘Silver Ivy’.The reason for the change from Yale to Samson is allegedly that Samson will be able to keep up with the demand for this product.

Petzl also released 2 ropes under their brand this year, the Petzl Flowand Petzl Control. The Petzl Flow is 11.6 mm with 2.8% elongation, and the Petzl Control is 12.5mm with 3.1% elongation. Both ropes have a 24 strand cover and meet CE EN 1891 type A, ANSI Z133.

Petzl also released 2 ropes under their brand this year, the Petzl Flowand Petzl Control. The Petzl Flow is 11.6 mm with 2.8% elongation, and the Petzl Control is 12.5mm with 3.1% elongation. Both ropes have a 24 strand cover and meet CE EN 1891 type A, ANSI Z133.The reason Petzl chose this Cousin-Trestec rope to sell under their brand is because the splice can be passed through the Zigzag and works well in conjunction with this mechanical device, so it combines perfectly with this Petzl product.

DMM also released some new pieces of hardware to their arborist range of products, including the new ‘Hitch climber Eccentric’ and new compact swivels .

Business news

Sherrill Inc. acquires Sterling rope company

Sherrill Inc., NC-based arborist and climbing gear company, this year acquired ME-based life safety rope manufacturer Sterling Rope Company Inc.Sterling is an industry leading rope manufacturer who has been supplying climbers, climbing gyms, arborists, search and rescue personnel, fire departments, industrial safety and the military for over 25 years.

Birch Lake Investments Ltd. Acquires ISC (International Safety Components Ltd.)

ISC said “The transfer of ownership provides Denny Moorhouse with a move into retirement after more than 50 years of industry-leading innovations in height safety devices. As a young adult, Moorhouse developed a passion for mountain climbing which led him to become a climbing instructor in the early 1960s. His enthusiasm for climbing continued to grow, and he soon looked for other ways to be involved in the industry. In 1966, Moorhouse established Clogwyn Climbing Gear Ltd, where he began manufacturing innovative climbing safety gear that eventually led to industrial safety products and what is now ISC.

Birch Lake Investments’ acquisition of ISC fulfills Moorhouse’s desire to see ISC remain an independent company.”

2019 competitions

Aerial resuce challenge by Wesspur

Wesspur held their first ever Aerial rescue Challenge event. This event was the brainchild of Dave Stice. The competition focused heavily on patient care in each event, using live patients, fake blood and sequestered competitors in order to give the most real life situation possible. The events also required all climbers to be permanently secured on 2 ropes in an attempt to educate each competitor in 2 rope climbing techniques along with integrating some SPRAT techniques. Word on the grapevine is, there will be more of these events in the future.

Champ Champ Scott Forrest!!!

August 2019 in Knoxville, TN, Scott Forrest won the ITCC for the fourth time. Josephine Hedger also took the women’s title for a fourth time.Later in the year in mid October, RedBull held their ‘Branched out’ competition in Kapunda, SA, Australia with 150 competitions. Scott Forrest put on some amazing climbs to take the winners trophy at the 3rd RedBull Branched out.

Safety standards and regulations news

It has long been looming, and over the last year or so the talk of climbing permanently attached to two separate climbing systems has become more common.The United Kingdom have become the first to make this system standard within arboriculture, and has been implemented by the ‘Health and Safety Executive’ (H.S.E.) The below paragraphs are taken from the Arboricultural association website;

Following the announcement in the Autumn issue of the ARB Magazine (issue 186, page 7) that the HSE is now requiring full compliance with the Work at Height Regulations in relation to tree climbing operations, there has been much discussion and debate.

The relevant section of the Regulations is Schedule 5, which addresses requirements for personal fall protection systems. See www.legislation.gov.uk/uksi/2005/735/schedule/5. The HSE has observed that some aspects of these requirements have been largely ignored by many climbing arborists, and that current training and assessment standards do not adequately address these issues.

The HSE has provided details of reported fall from height accidents for a one-year period, which can be viewed on the AA’s website: www.trees.org.uk/2ropes-incidents. The background to this wider issue can be viewed here: www.trees.org.uk/2ropes.

Final thoughts

Let’s all see a safe end to 2019. For our families, friends and ourselves let’s continue in the goal to be safer at work and help keep our colleagues safe, after all we work as a team, we should work to be safer as a team.Happy holidays, Merry Christmas and a happy new year to all. Wishing you and your family a happy and healthy end to 2019 and into 2020.

Changing lives one tree at a time

by

Blog post written by: David Anderson (Canopy watch international)

Trepadores every one. Hardy climbers and instructors Discovering the Canopy the Colombia way. Photo © Felipe Barrera

Trepadores every one. Hardy climbers and instructors Discovering the Canopy the Colombia way. Photo © Felipe Barrera“clap . . . clap . . . clap-clap-clap

clap . . . clap . . . clap-clap-clap”

The sound of clapping hands splashing through the tropical forest of Colombia, growing in volume, bouncing off tree trunks and leaves,

“clap . . . clap . . . clap-clap-clap”

louder and louder, until the refrain reaches a crescendo, joined by a call: “UNO . . . DOS . . . TRES . . . ¡TREPADORES!” 24 voices shouting in unison “¡CLIMBERS!”

And so begins a typical day for the decidedly atypical Descubriendo el Dosel 2019 (Discovering the Canopy 2019), our most ambitious climber training ever. In a burst of applause, 19 students and four instructors spread into the forest, helmets on heads, ropes in hands, in search of trees to climb and new skills to learn and master.

During a steamy, sunny week at the Río Claro Nature Reserve in Colombia, we have a big target ahead of us: Turn 19 biologists from Latin America–novice climbers every one—into competent and confident tree climbers, ready to return home to ascend their own local forests for conservation research that no one else is doing. It’s a part of our mission to bring canopy access—and canopy conservation—to the world, one climber and one country at a time.

Climber training is a beautiful thing. Every tree is a riddle to solve, every technique and piece of equipment is new. Men and women who spend their lives walking the ground and who normally consider heights a dangerous thing are now asked to hang their lives on ropes that have the diameter of a dime. Below each tree two biologists sporting bright yellow Petzl helmets shout encouragement and advice to their colleagues nervously making their way up, down, and around lush tropical trees. Instructors on Yale ropes keep an eye on technical details, watching for safety every second. By opening the minds of students, and leading them to unlock problems for themselves, they will be prepared for the careers to come when no one will be there to explain what to do next or to check on their safety.

The essence of climber training: students on rope, in trees, learning from each other in challenges they couldn’t have predicted. Photo © Juan Carlos Rivas.

The essence of climber training: students on rope, in trees, learning from each other in challenges they couldn’t have predicted. Photo © Juan Carlos Rivas.We are here to teach and learn. Every day there are new pieces of equipment that are introduced, their proper and improper uses explained. How do you arm a climbing system to get you up a rope efficiently and safely? Where do you attach ropes to your harness when you’re climbing vs. when securing your position to a trunk or branch? Hands, arms, legs all repeat new motions so many times that they start to react with muscle memory that didn’t exist a week earler, until a motion that felt unnatural and clumsy on Day 1 happens smoothly and instinctively on Day 5. And always there are the trees. How do you put a climbing rope 100 feet into a tree while standing on the ground? How do you move across the entire width of a tree while suspended on a rope? How would you go out on a branch, then lock into your position so you can install a camera trap without swinging out of place? These images are textbook definitions of training.

Yet we work on something more fundamental than equipment function and muscle memory: We work on the heart. New climbers are trusting their lives to us every day.“Walk out on that branch 20 feet. Trust me.” More importantly, minute by minute, hour by hour, we build their trust in each other and in themselves, for preparation when we’re gone. “Swing your body from this tree to that one and stay put. Trust yourself.” Conquering fear with trust builds self confidence and changes lives. It takes the old you and makes someone who is stronger and wiser, who is able to do more and better work. The hand clap that calls all climbers back to base before and after every exercise? It’s no accident. It takes the role of authority, and of trust, from the hands of instructors and puts it directly into the hands of the students. Quite simply, it takes a group of students and instructors and makes us family.

Textbook photo for the definition of “climber training”: Luz Adriana Molina limbwalking and pushing beyond her limits. Photo © David L. Anderson

Textbook photo for the definition of “climber training”: Luz Adriana Molina limbwalking and pushing beyond her limits. Photo © David L. AndersonIf there is one lesson that came out of this grand experience it is this: Dream Big. The idea behind Descubriendo el Dosel 2019 was grand and big, improbable if not impossible. We sought no less than to hand the reigns of conservation science over to local biologists who live and breath and work and raise families in imperiled forests.

Family. It makes us stronger and better, and is what Descubriendo el Dosel is all about. Photo © Felipe Barrera.

Family. It makes us stronger and better, and is what Descubriendo el Dosel is all about. Photo © Felipe Barrera.So Lesson #2 follows: When you want to dream big, take your friends along. This training was a success because of friends and partners who were absolutely critical to this effort. First and foremost, Fundación Alianza Natural, (LINK) a non-profit conservation organization in Colombia, was the official host of this event and did all the in-country organizing and prep. Petzl Foundation(LINK) came in early as our official Hardware Sponsor, donating helmets, harnesses, carabiners, lanyards, and a long list of vital equipment. Yale Cordage(LINK) was the event’s official Software Sponsor, donating miles of rope, literally.